Products > Bottle and can transport systems

Bottle and can transport systems

You are on the Bottle and can transport system subpage.

Click here to go to the Pack and carton transport, Tray and crate transport, Palletising technology or Special solutions section.

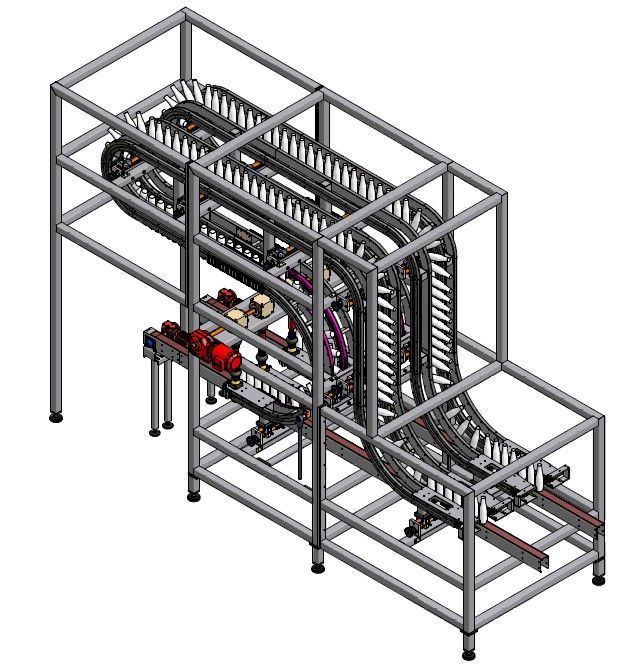

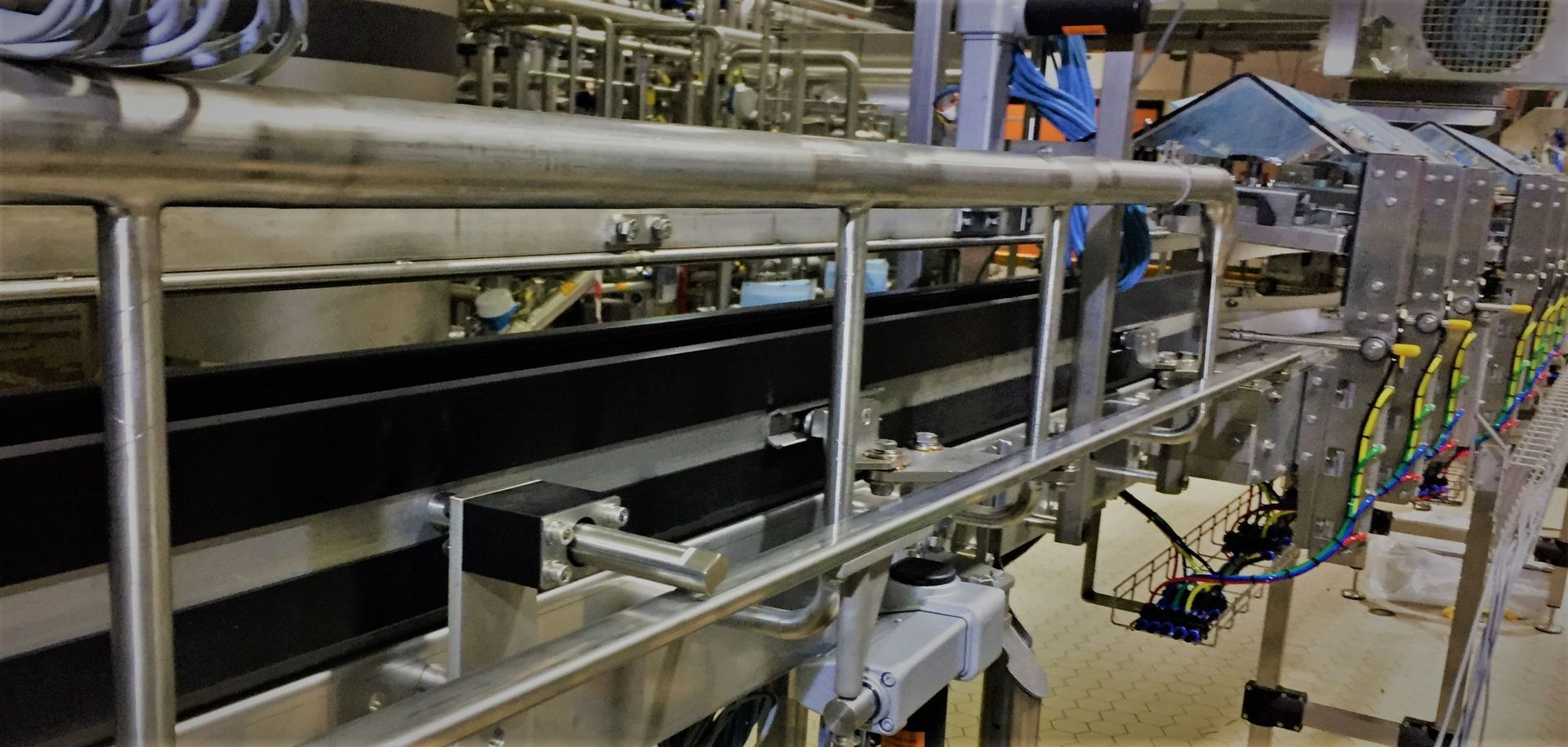

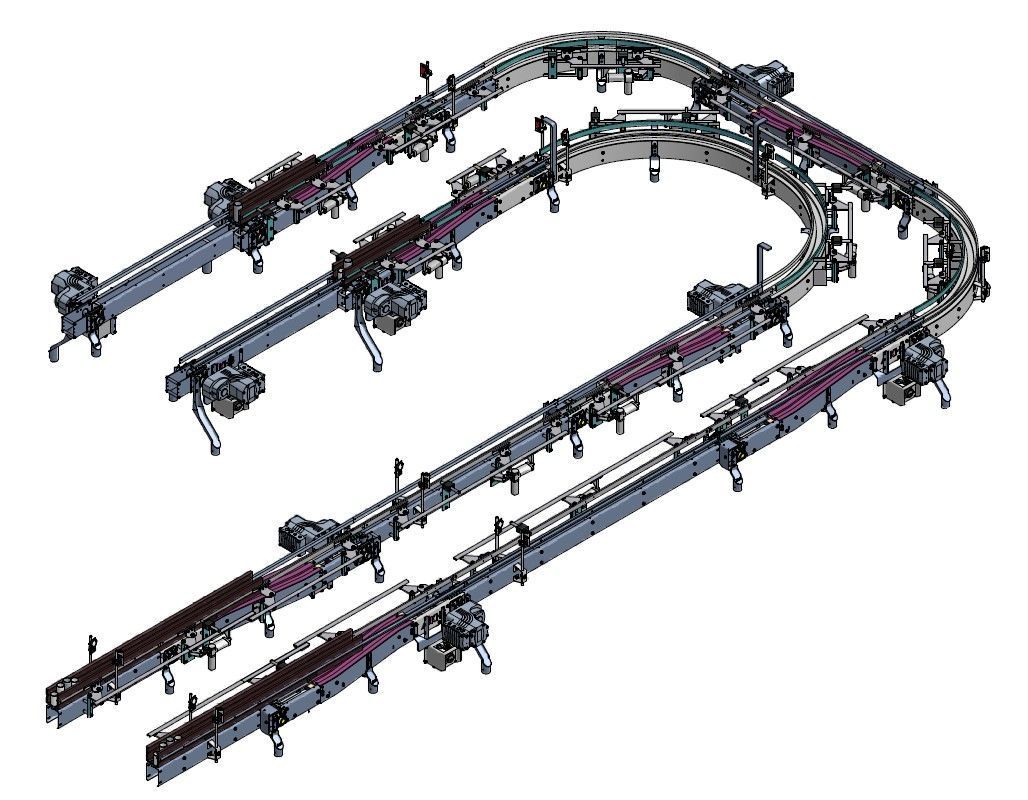

Our conveyor systems are manufactured in-house using a modular system made of type 304 stainless steel and plastic

Single- and multi-track conveyor systems are indispensable in a filling line.

Assembly with connecting straps is fast, easy and safe; it also allows rebuilding and redeployment at any time.

The cleverly coordinated use of the various components of the PAXONA AG modular system enables project planning of a system with a capacity of 1,000 to 100,000 bottles/h that is perfectly tailored to the respective product and the specific conditions.

Our design department will individually plan your product or system according to your requirements.

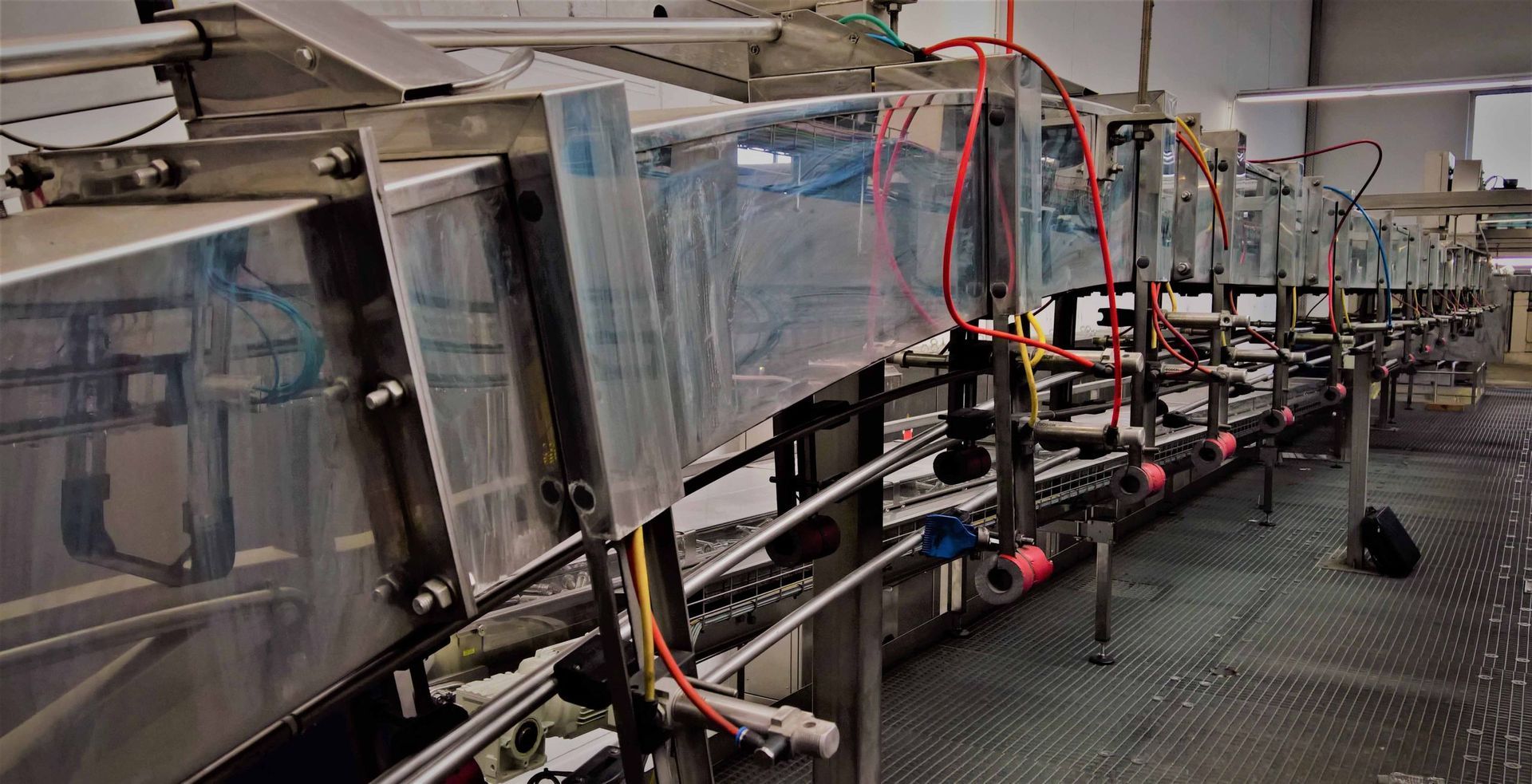

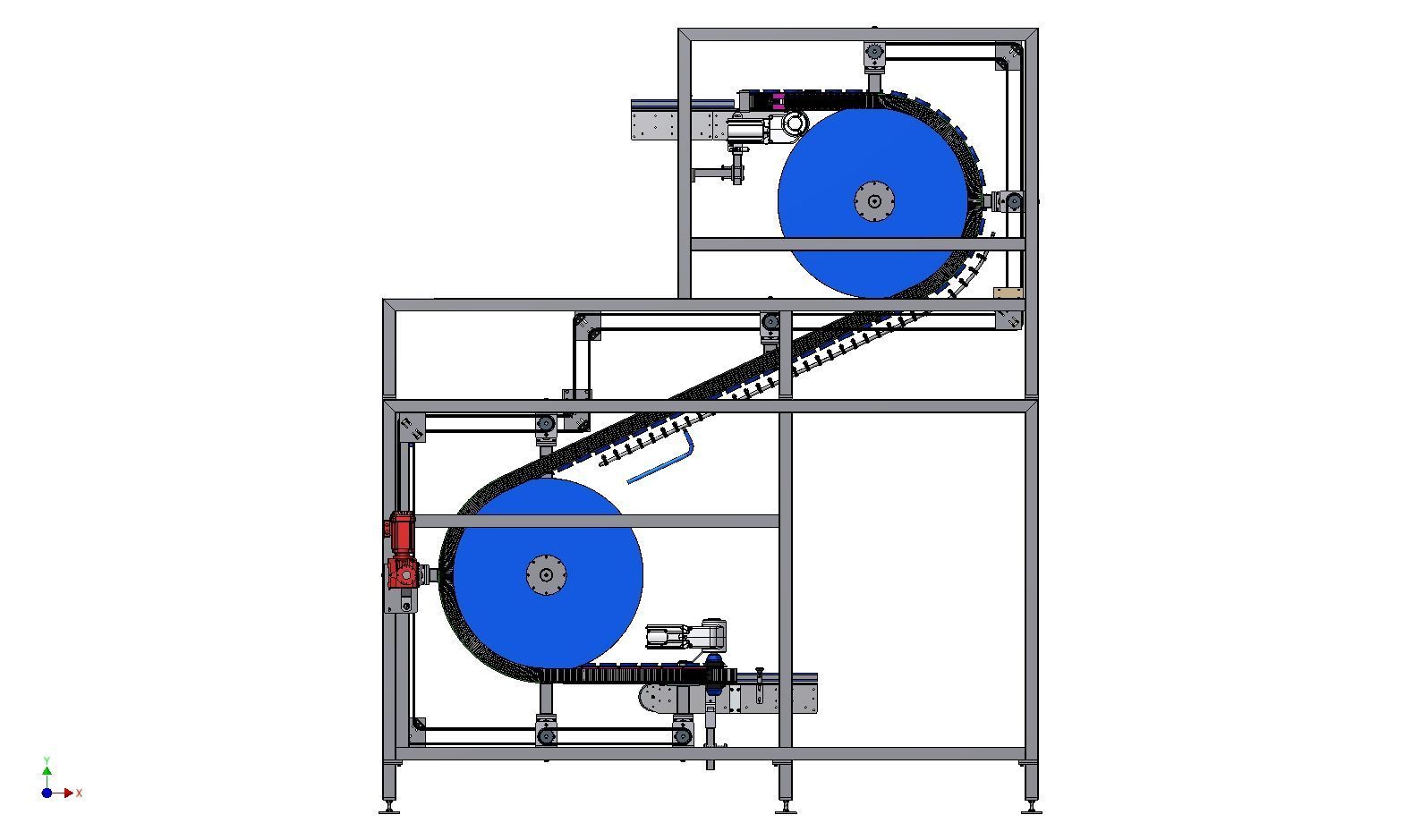

Air transport for plastic bottles

Air transport for plastic bottles

We can easily provide air transport solutions with any of the following designs: one- or two-way, one above the other, with or without an aseptic environment.

The guides can be set manually or automatically via air cylinders and electric valves.

The air conveyor systems are equipped with dual-filter fans and directly mounted on the air housing.

Whether you want them standing on type 304 stainless steel feet or mounted on the ceiling, that’s no problem for us.

With our air conveyor systems, any obstacle can be overcome.

Our conveyor system can be equipped with specific elements such as rejecters, sorters or a CIP cleaning system.

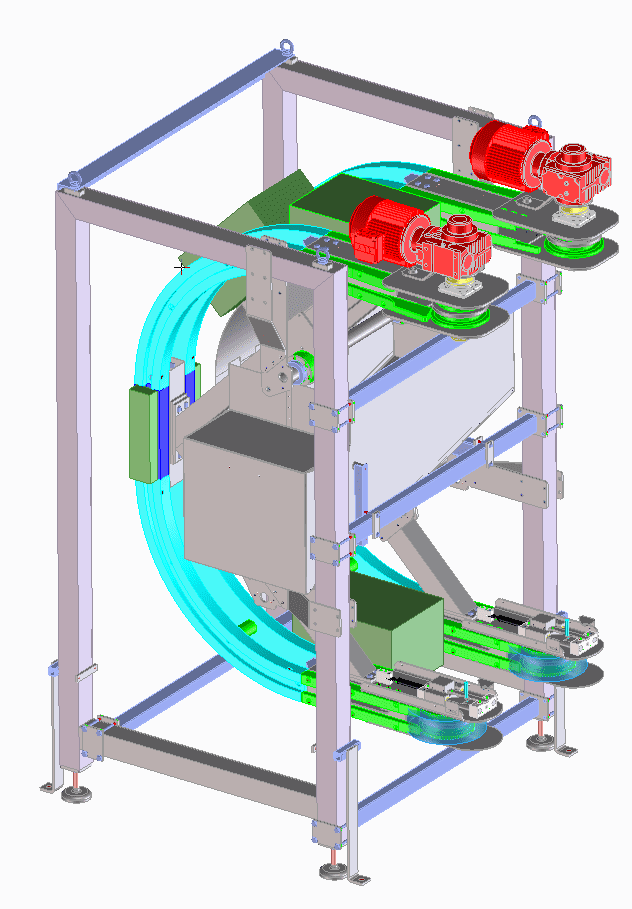

Gripper conveyor

The Paxona gripper conveyor for bottles, cans and round containers is made entirely of type 304 stainless steel.

The bottles, cans or similar containers are conveyed vertically between two rubberised chains.

The drive is synchronous.

The material to be conveyed is gently clamped between the two chains.

The conveyor system works continuously, thereby allowing efficient line operation without excessive noise.

The drive consists of a special construction with conical gear wheels running in a closed oil bath.

The gear wheels, which are mounted on a shaft with a drive, can be moved laterally.

This drive shaft and the adjusting screws are protected by a sleeve.

This concept and the all-type-304 steel construction make this gripper conveyor unique and suitable for wet environments, e.g. in the filling industry.

The conveyor is ideal for small spaces in combination with other means of transport, such as slat-band chains.

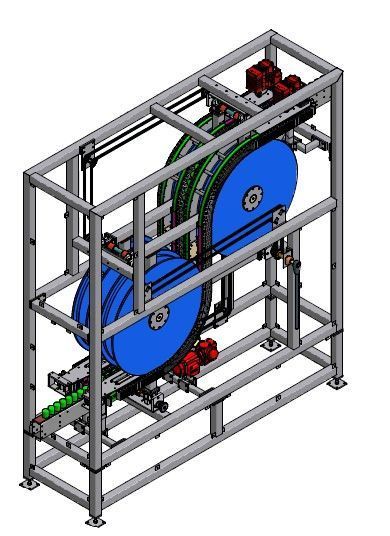

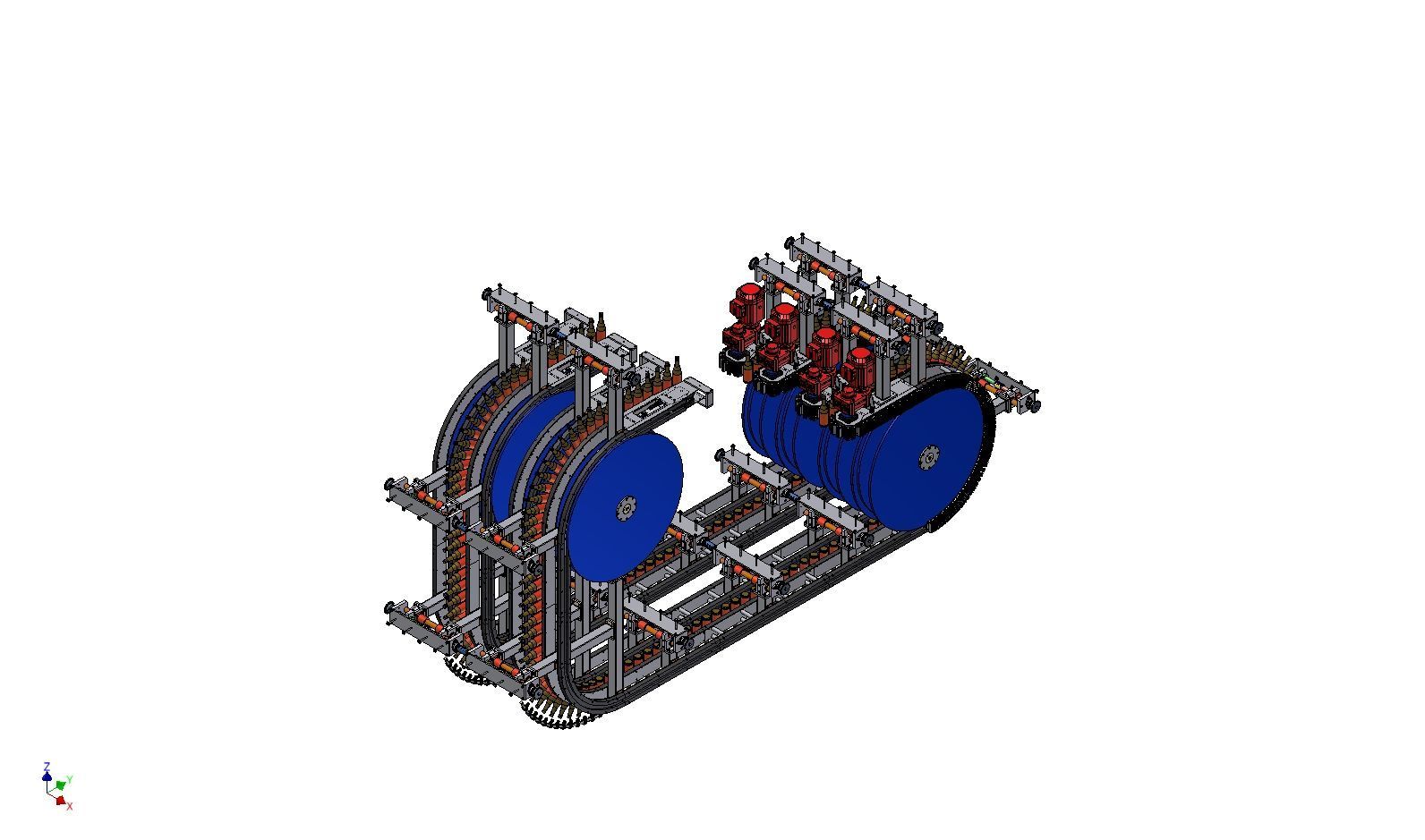

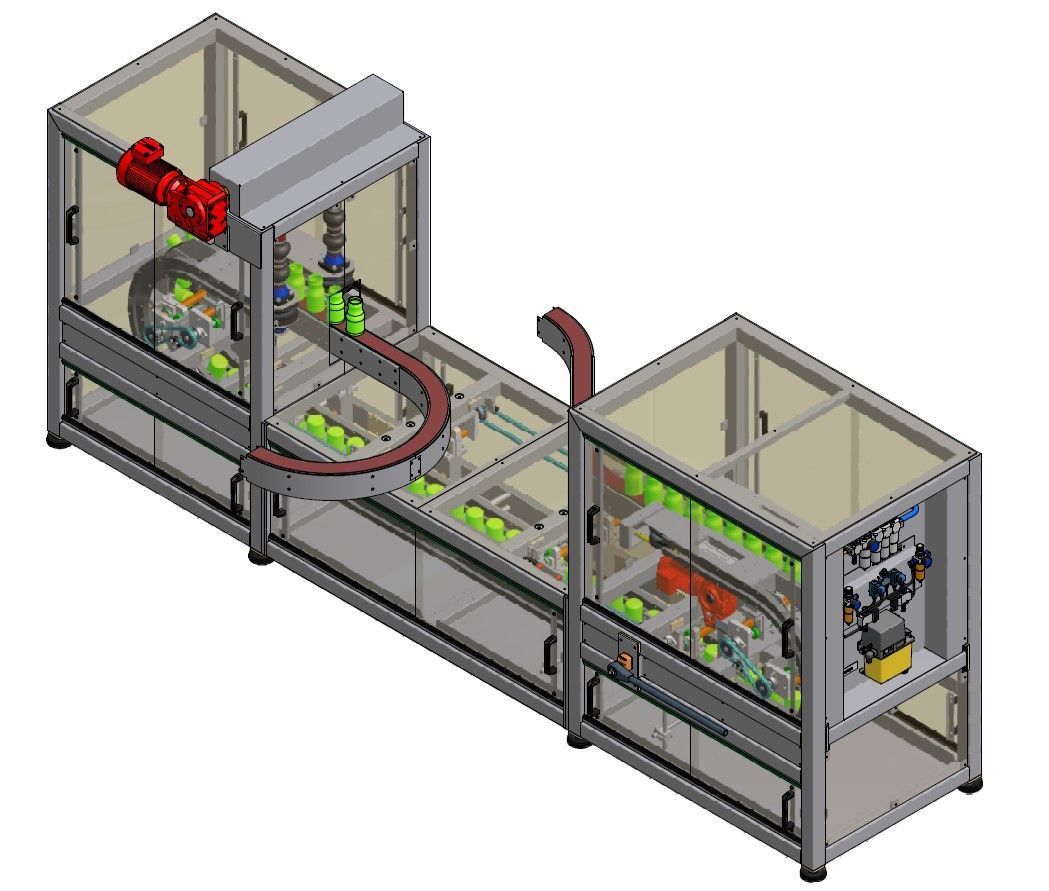

New glass depalletiser

With the GLASEX product range, Paxona AG offers a versatile machine system for both medium and high capacities.

The machine is ideal for the safe removal of bottles, jars and cans as well as canisters of various shapes and types that are situated on intermediate layers and can be safely pushed off the packing layer.

The easily accessible and maintenance-friendly machine features high corrosion protection through triple surface treatment and is available in painted or stainless steel versions, depending on requirements.

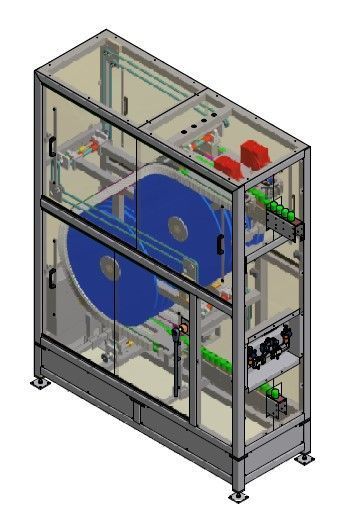

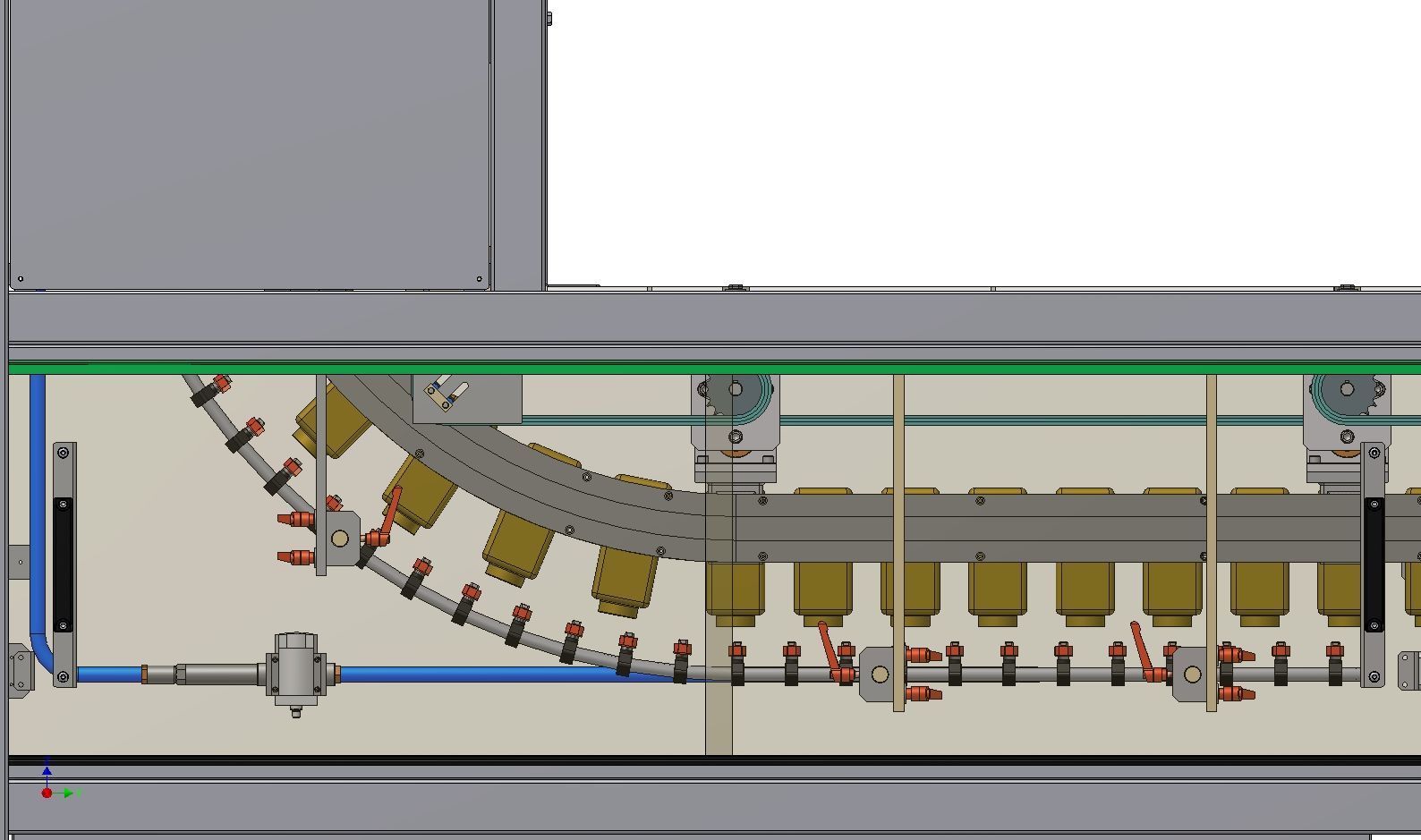

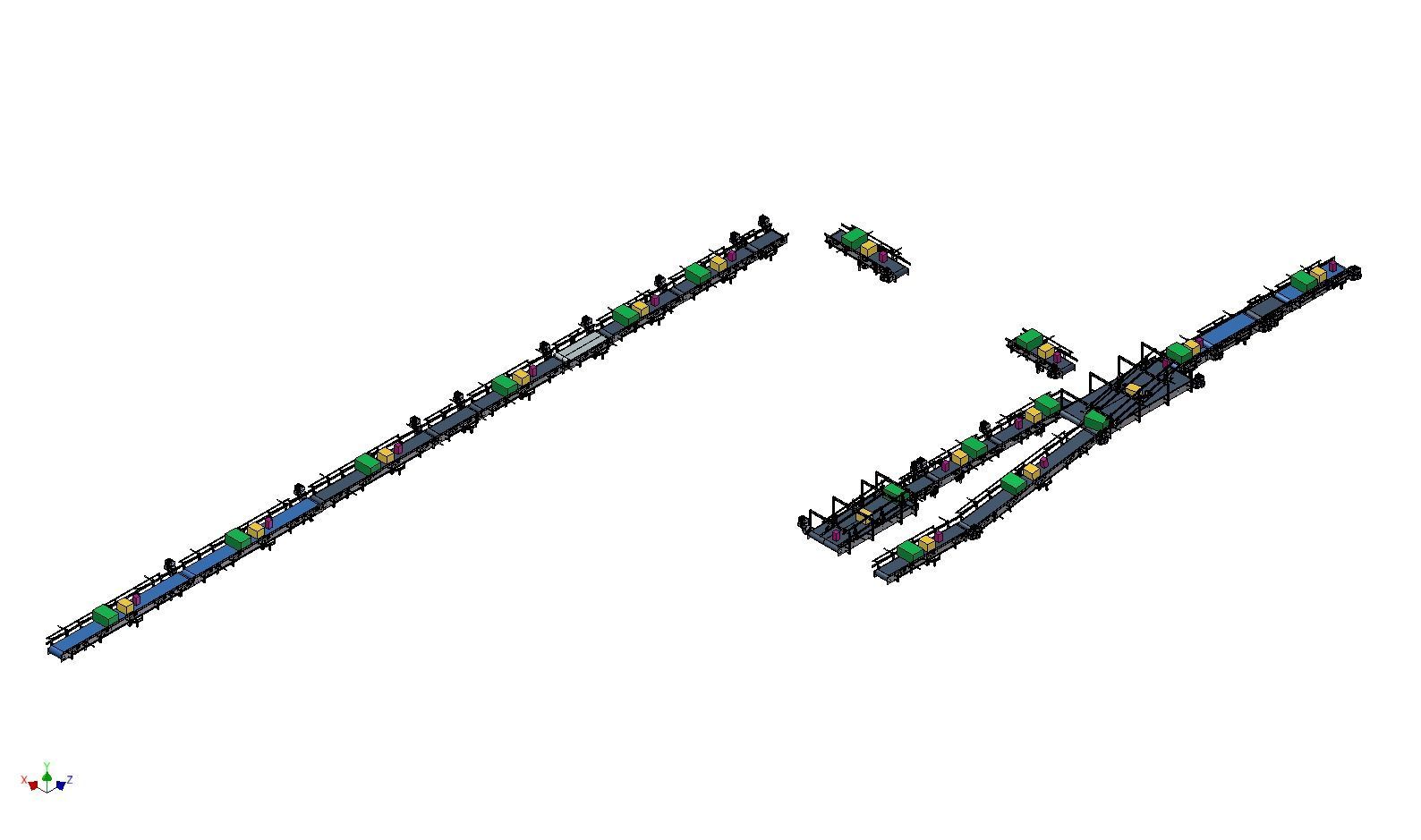

Synchroweiche sorter

The sorter that puts your moulded products on the right track.

It is a familiar problem all across the world:

at one time, moulded containers, bottles, cans and the like could only be distributed between different lines by using a clamping and shifting system, but this reduced the output of the line.

Today, there is a simple and economical solution for this in the form of our very own Synchroweiche sorter, which guarantees continuous, precise and safe product transport.

Good product flow, accompanying of the product and fast and safe format changeover all result in a highly efficient line.

The distribution guide is synchronised with the speed of the product, which is continuously guided on both sides, without impact or damage.

The lateral guides ensure the stable footing of the conveyed material while in motion.

Any lane and distribution rhythm can be easily selected by entering them on the touch panel.

Adjustments can be made during format changeover without special tools, meaning that no loss of production occurs and the belt speed is maintained.

The Synchroweiche sorter is suitable for the food, beverage, chemical, pharmaceutical and cosmetics industries.

Linear rinser for bottles and cans

The linear rinser for bottles and cans is based on the concept of a gripper conveyor.

Both incline and decline conveying are possible.

The product is manufactured from stainless steel and features an electropneumatic controller for the chain tension, injection nozzles and troughs made of type 304 stainless steel.

The chain spacing can be automatically controlled via electric motors.

The linear rinser can be individually adapted for each line.

Pressureless bottle combiner

The pressureless bottle combiner is suitable for capacities of up to 100,000 bottles per hour.

The output of the lead machine and the bottle quantity on the conveyor belts are monitored using signal transmitters.

A microelectronic control system processes the signals and controls the drive motors via frequency converters.

We guarantee no bottle jamming, rejection of broken glass and lying bottles without machine stoppage.

The pressureless bottle combiner runs quietly with minimal bottle wear.

Another advantage of this unique Paxona product is that no changeover work is required for a different bottle type.

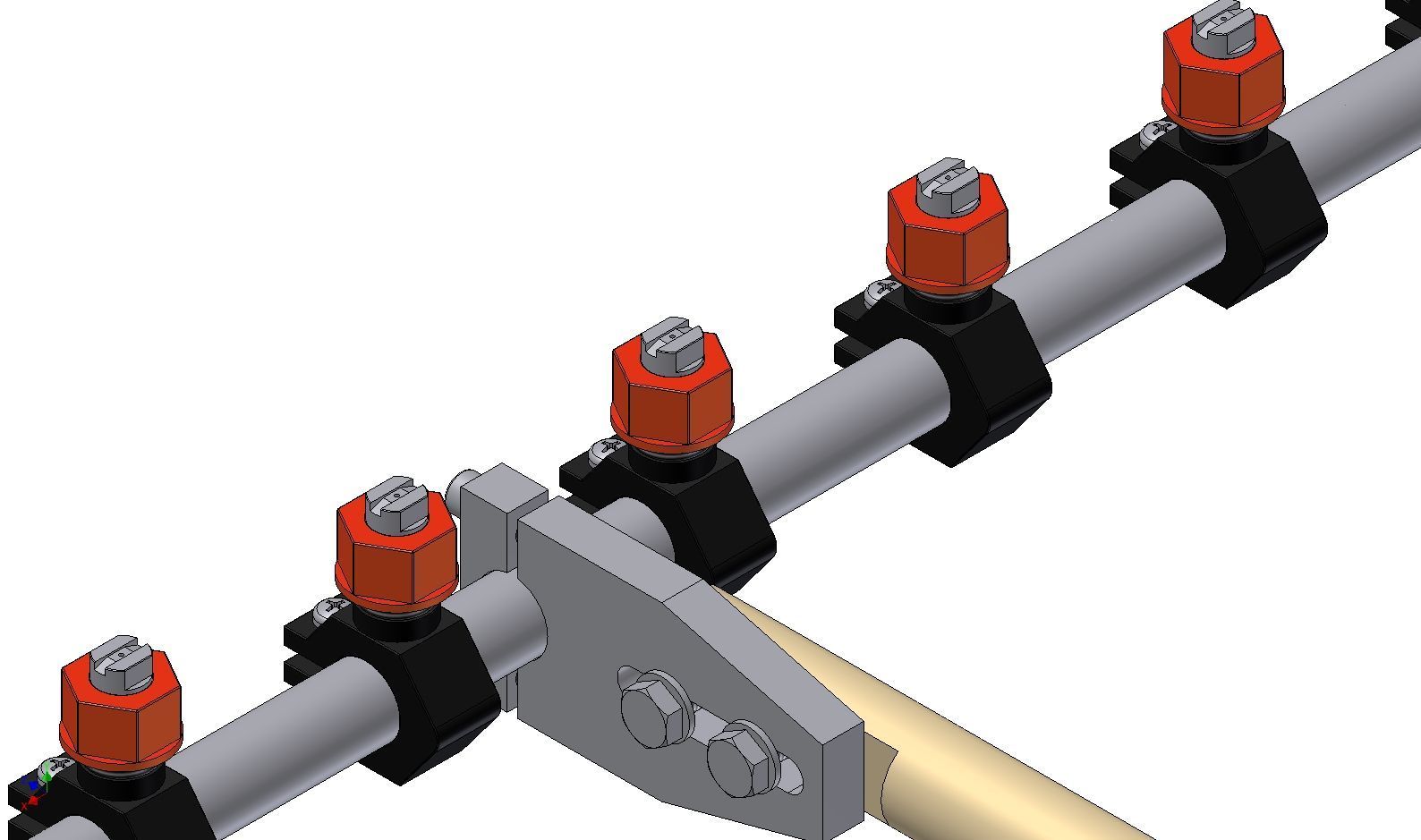

Automatic guide adjustment

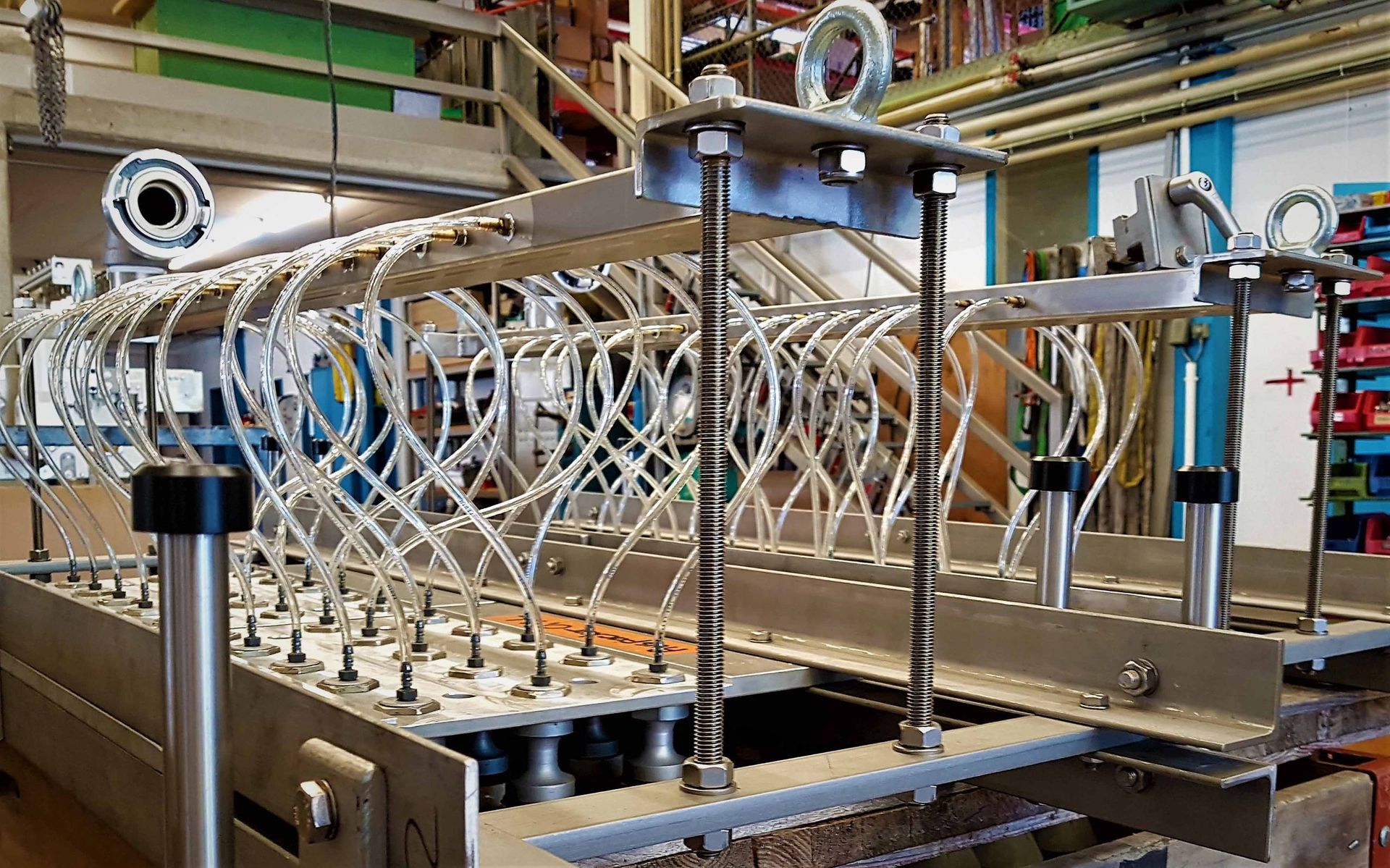

With the unique automatic guide adjustment from Paxona, the units in the individual sections are brought together at one point, from where the cables are routed to the control system.

The different guide positions are defined in the program so that the selected position is approached in each case.