Products > Tray and crate transport

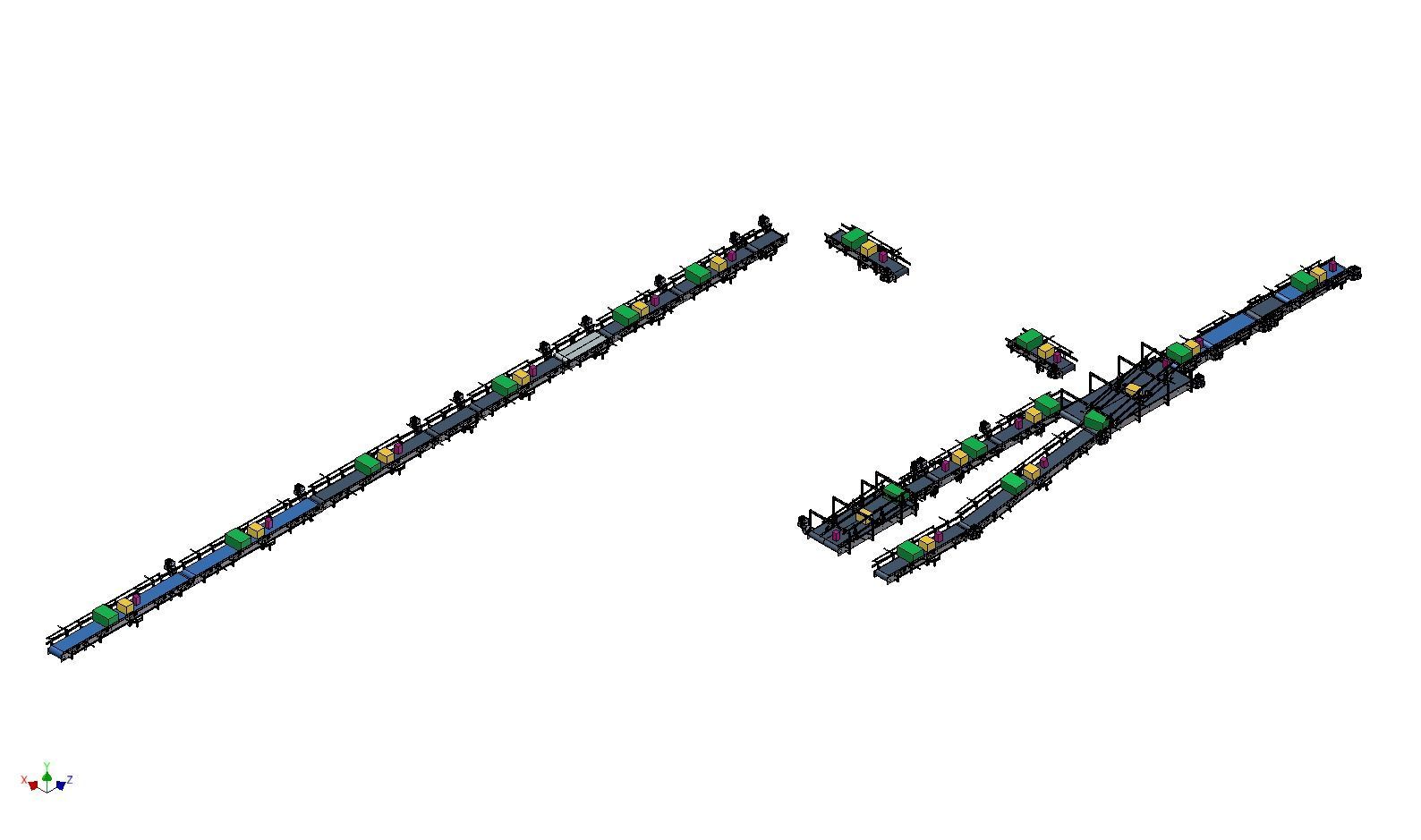

Tray and crate transport

You are on the Tray and crate transport subpage.

Click here to go to the Bottle and can transport systems, Packs and carton transport, Palletising technology or Special solutions section.

Whether it’s a matter of stacking, turning or transporting – our crate transport technology will meet all your requirements.

We would be delighted to plan, manufacture and install the crate transport technology you need for your innovative project.

Paxona manufactures various transport units, trays and carton conveyor systems, and we attach great importance to their quality and efficiency.

Chain belt conveyors (single-lane, double-lane)

Roller conveyors (gravity, powered, accumulating)

Belt conveyors (stop belts, cycle belts, incline conveyors, decline conveyors)

Spiral conveyors (incline, decline)

Crate slide

Elevating conveyors (incline, decline)

Crate turners

Guides depending on the conveyed material (entire structure made of type 304 steel)

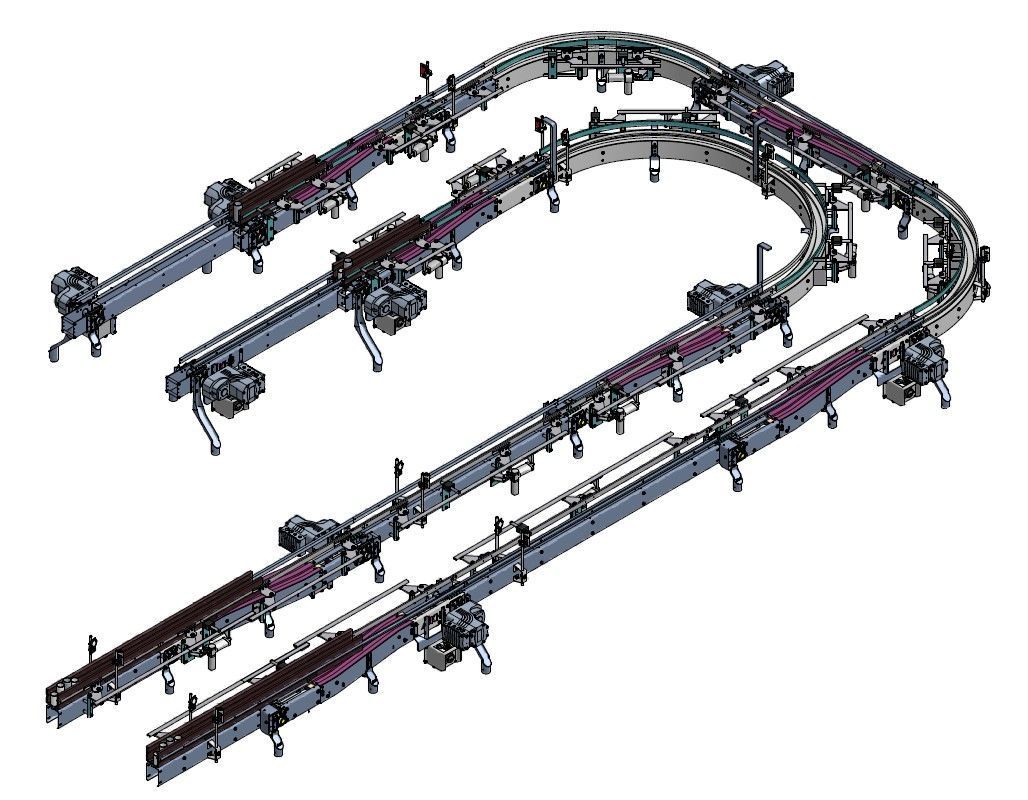

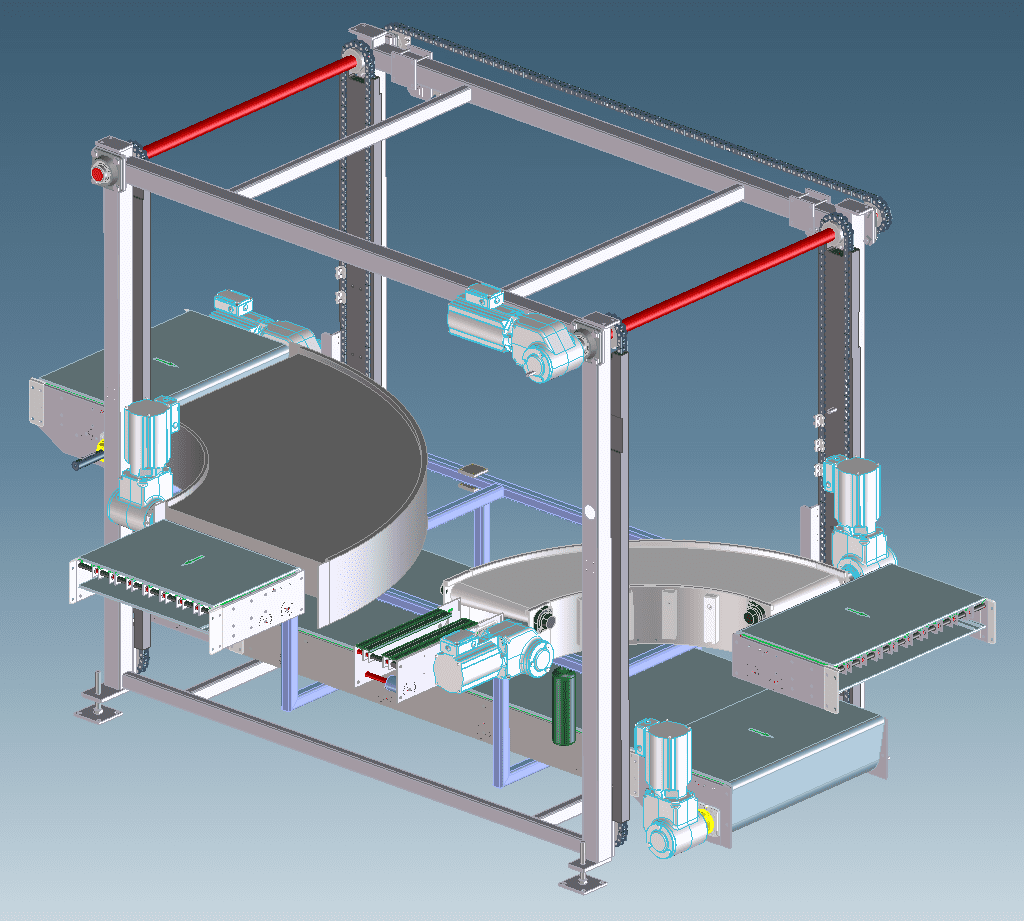

Synchroweiche sorter

The sorter that puts your moulded products on the right track.

It is a familiar problem all across the world:

at one time, moulded containers, bottles, cans and the like could only be distributed between different lines by using a clamping and shifting system, but this reduced the output of the line.

Today, there is a simple and economical solution for this in the form of our very own Synchroweiche sorter, which guarantees continuous, precise and safe product transport.

Good product flow, accompanying of the product and fast and safe format changeover all result in a highly efficient line.

The distribution guide is synchronised with the speed of the product, which is continuously guided on both sides, without impact or damage.

The lateral guides ensure the stable footing of the conveyed material while in motion.

Any lane and distribution rhythm can be easily selected by entering them on the touch panel.

Adjustments can be made during format changeover without special tools, so that no loss of production occurs and the belt speed is maintained.

The Synchroweiche sorter is suitable for the food, beverage, chemical, pharmaceutical and cosmetics industries.

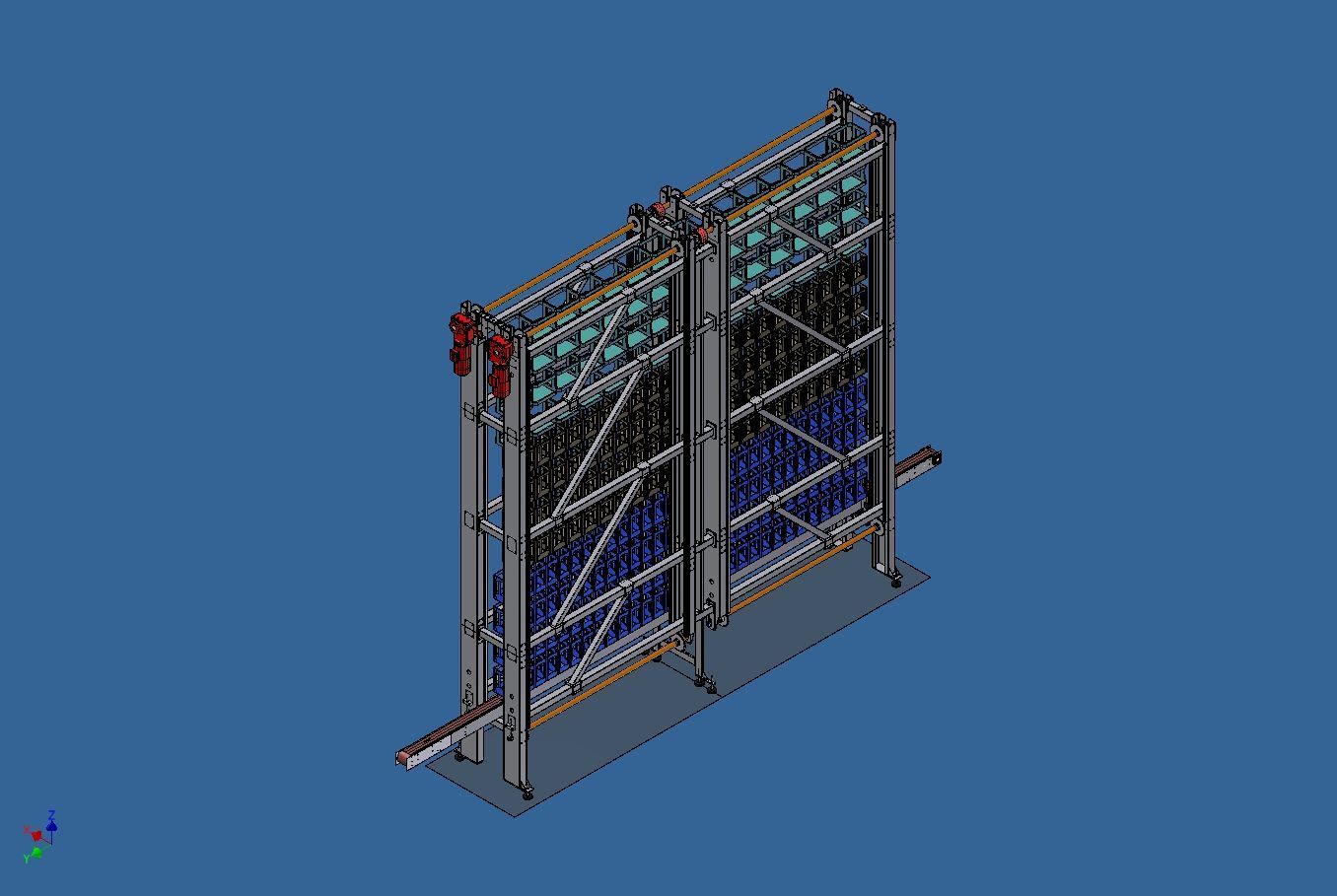

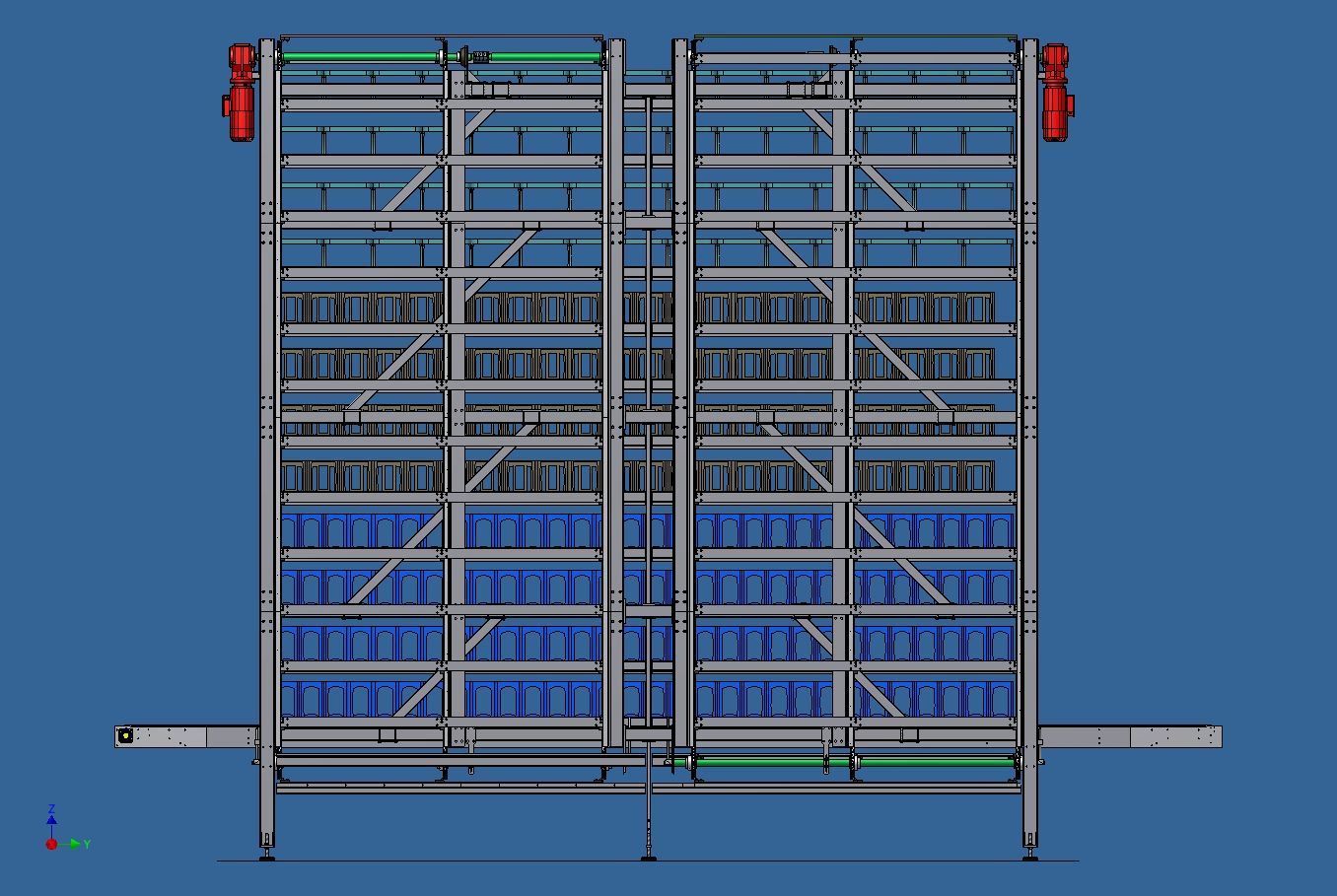

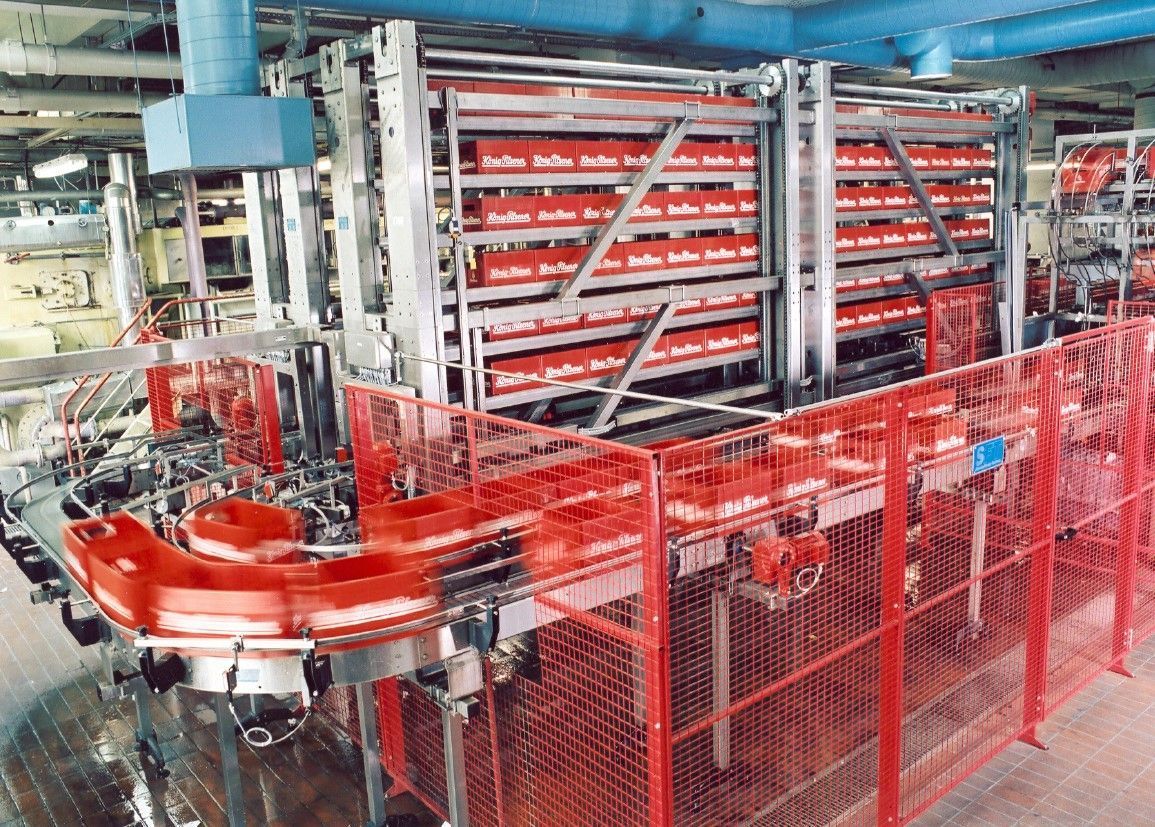

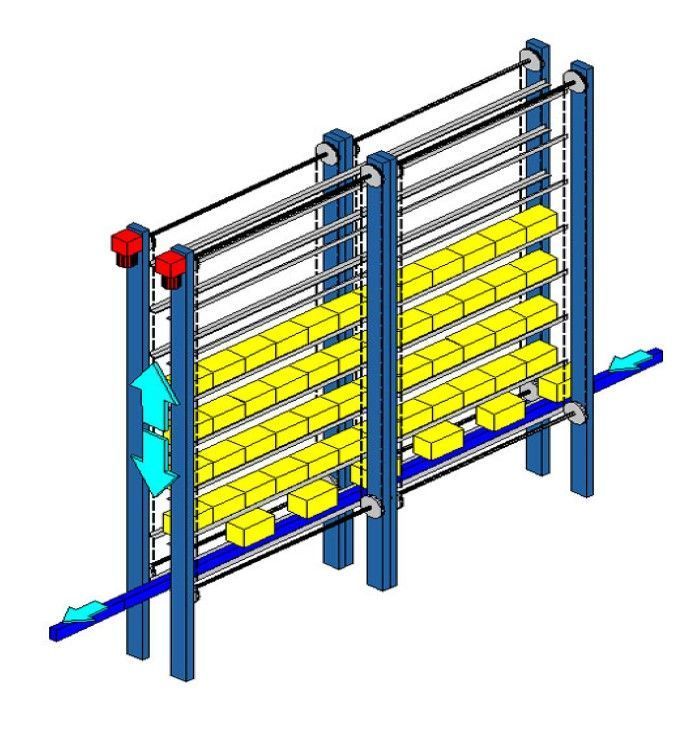

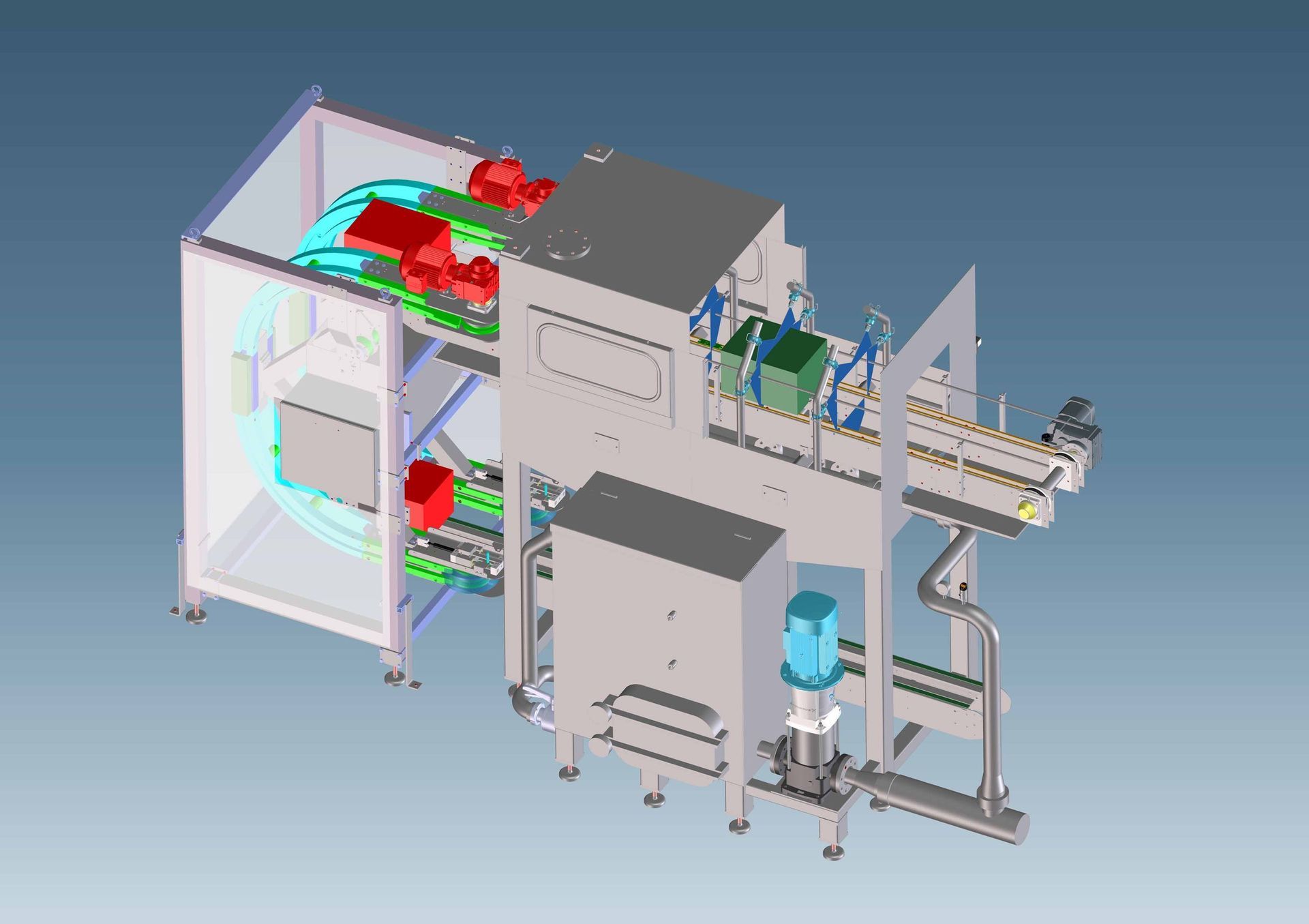

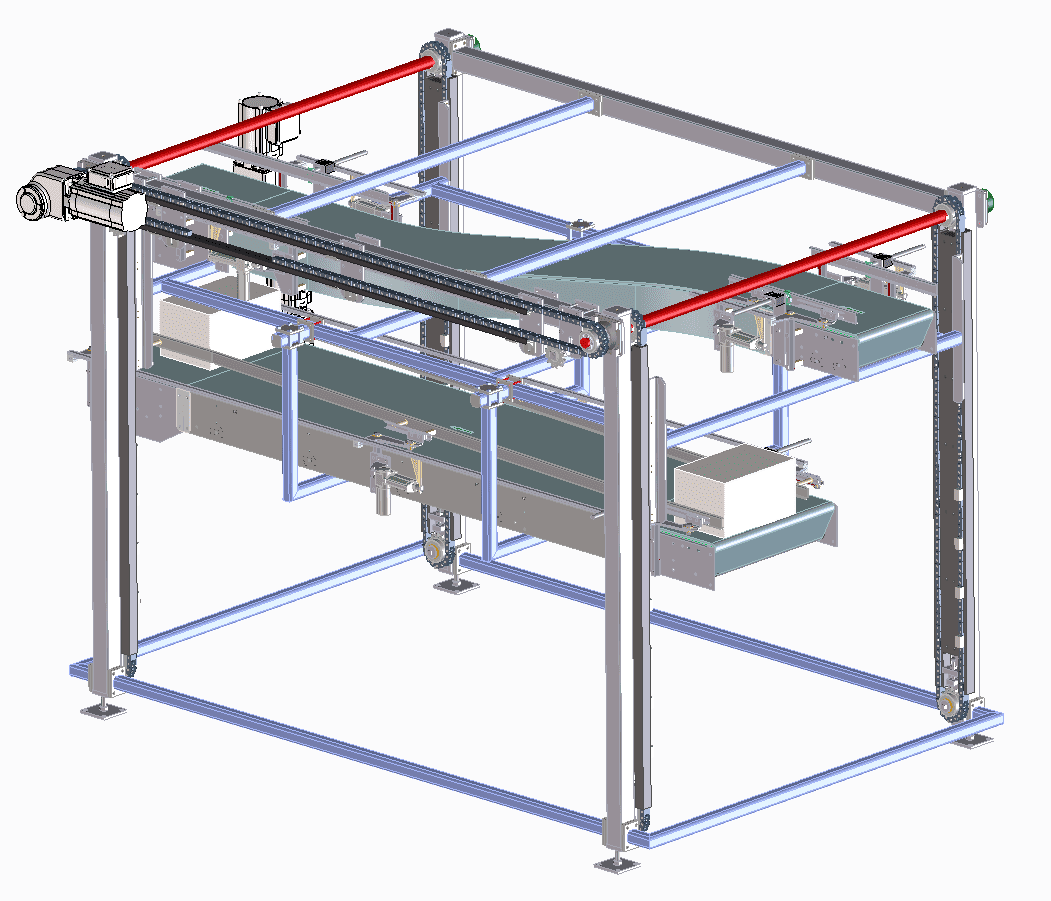

Dynamic crate magazine

The dynamic crate magazine is built entirely from type 304 stainless steel and consists of a vertical lift via two roller chains and a dual synchronised drive.

The crate support consists of a type 304 stainless steel bracket.

The unit is installed via an integrated slat-band chain conveyor including an electric and electro-pneumatic controller.

The installation dimensions are variable depending on the product and requested crate quantity.

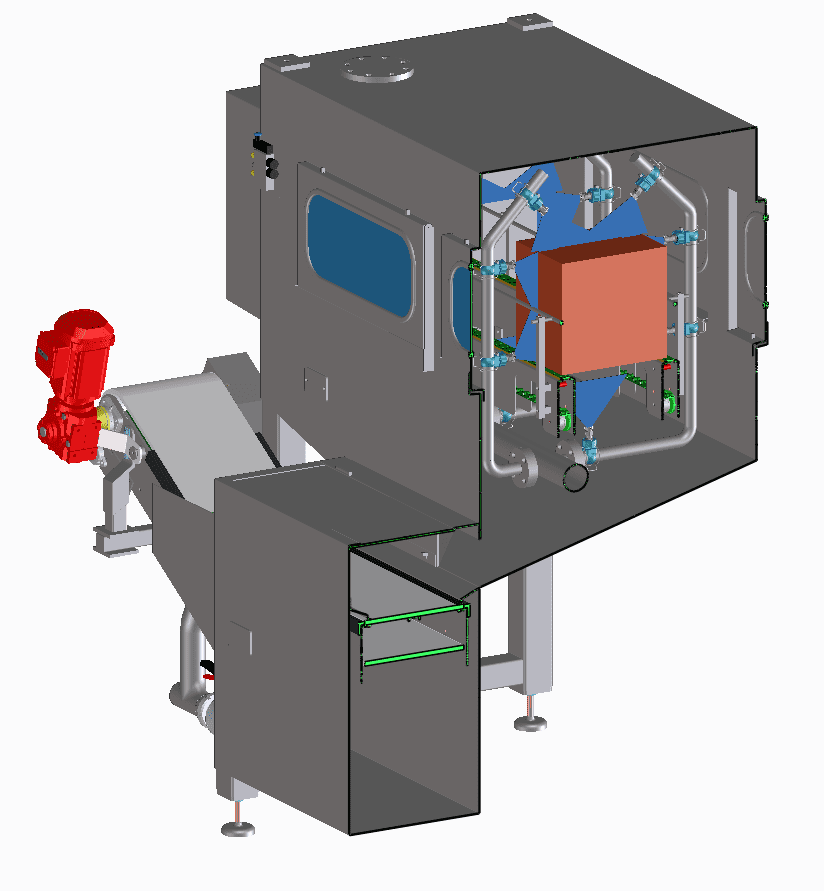

Crate washer

The Paxona KW 3000-1 crate washer in a chrome-nickel steel design has a capacity of 500 to 6,000 crates per hour.

This can be manufactured as desired: with a single or double-lane design, as well as with one or two levels.

The sieve container on the side of the KW 3000-1 allows for simple and easy cleaning.

This can also be manufactured as a special version combined with a label remover.

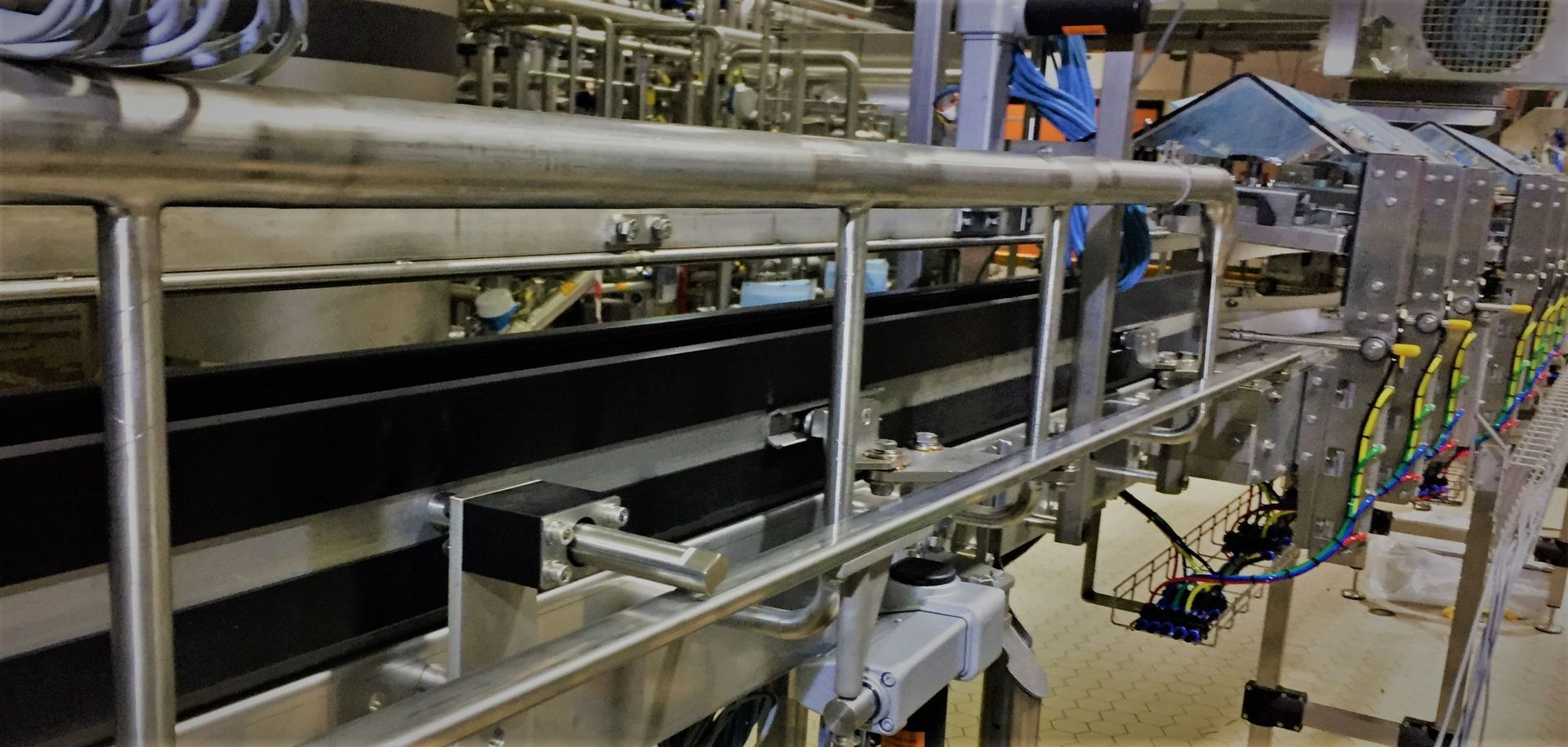

Automatic guide adjustment

With the unique automatic guide adjustment from Paxona, the units in the individual sections are brought together at one point, from where the cables are routed to the control system.

The different guide positions are defined in the program so that the selected position is approached in each case.

Pack manipulator

For product turning, the Paxona pack manipulator is increasingly replacing the conventional bump-turn device.

The ability to manipulate packs in this way gives you maximum flexibility in terms of the layer pattern.

The advantages of the pack manipulator lie in its ability to handle all product types gently.

In addition, the turning router is even able to process trays with low edges.

The manipulator has already established and proven itself in high-capacity scenarios.

The Paxona pack manipulator distributes, turns and brings packs together – regardless of the type.

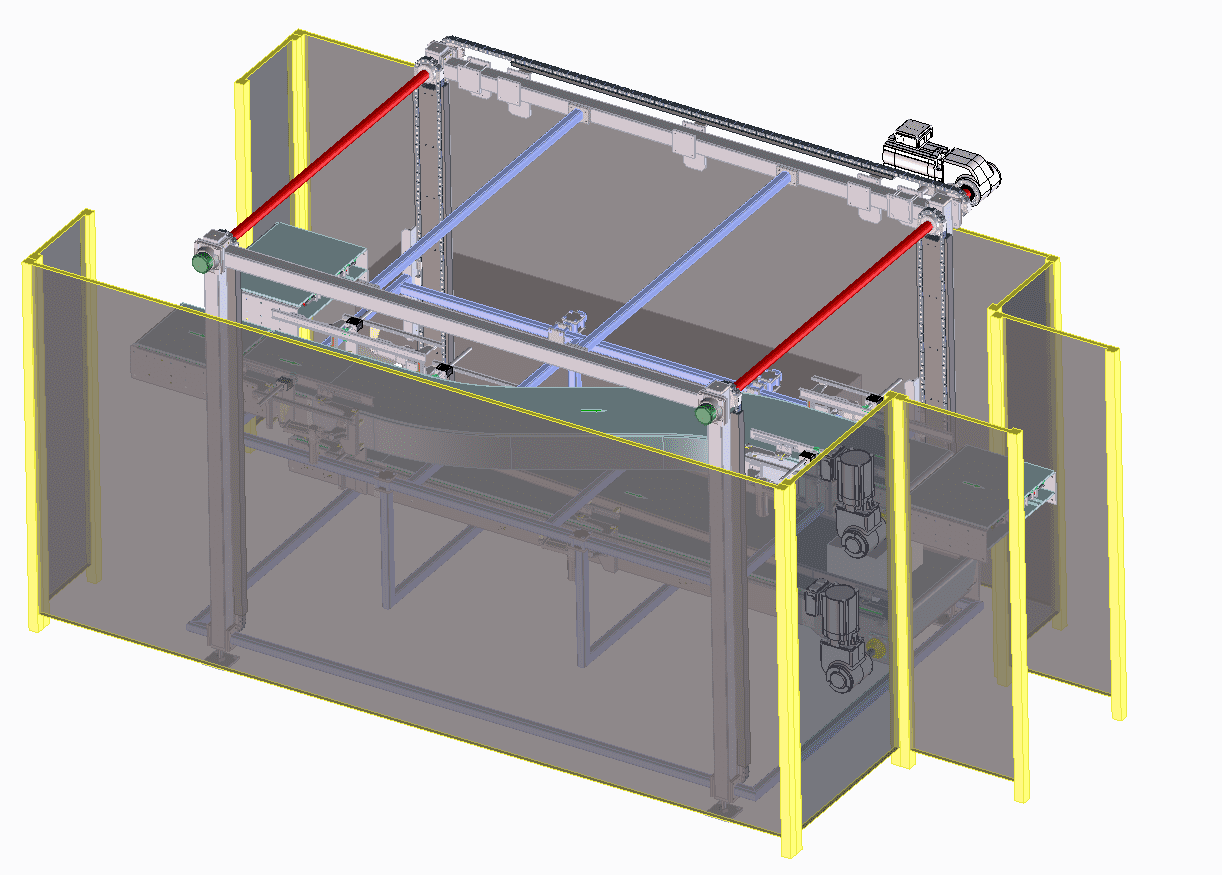

Lifting station

Our lifting station, made of chrome-nickel steel, can be used as an alternative to the line distributor.

The station is planned, assembled and electrically prepared at our plant and then quickly integrated into the line on site.

Implementation requires modification of various components in the control cabinet and control system adjustments.

The complete lifting station is enclosed by a protective fence, which has a sliding door function on one side to enable any maintenance work to be carried out.

A separate emergency stop relay is installed with this in mind.

Inputs and outputs are provided for the key access system.